Product Description

1. Product Definition and Overview

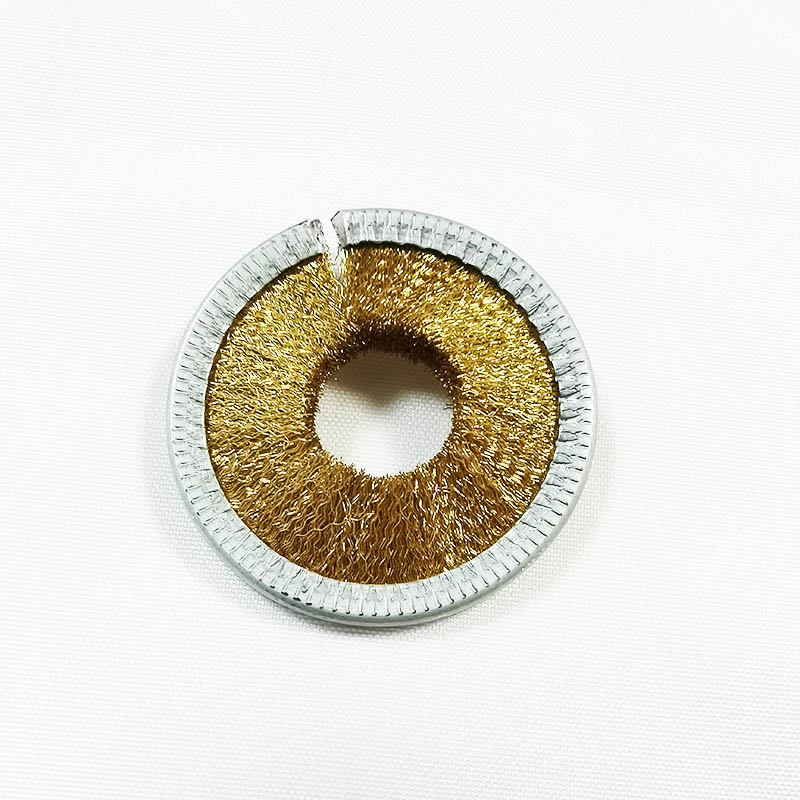

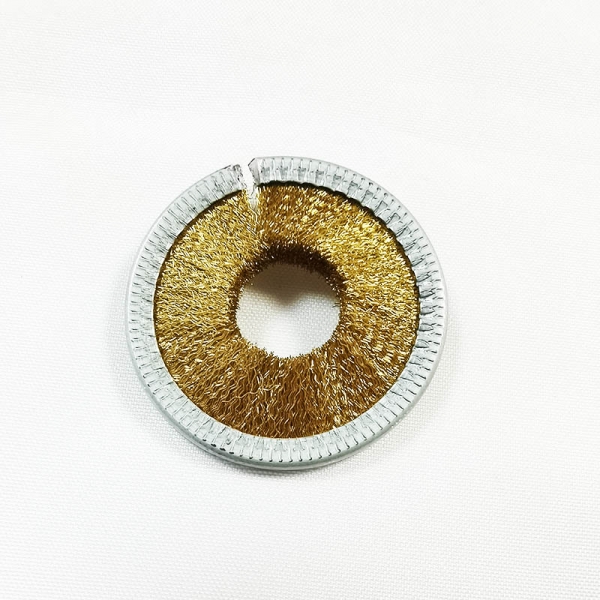

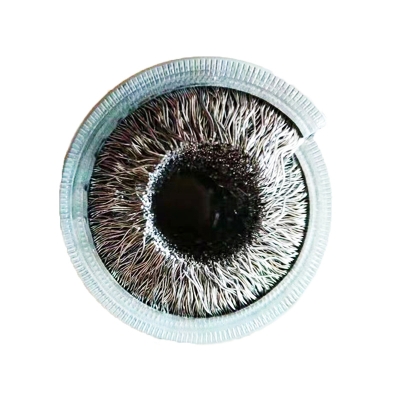

The brass wire single-piece brush is first pressed into a strip brush and then wound into a 360-degree arc shape. It is composed of high-quality brass wire and a solid metal base. The brass wire is flexible, wear-resistant and corrosion-resistant. It is suitable for surface grinding, rust removal, deburring and polishing of metal, wood, plastic and other materials. It is widely used in metal processing, machinery manufacturing and other industries..jpg)

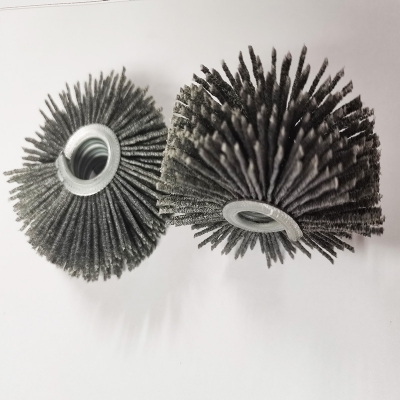

2. Process Highlights

|

Process Dimensions |

Technical Details |

User Benefits |

|

Brass wire selection |

Selected high-quality brass wire, with excellent flexibility and strength |

Not easy to break, prolongs service life |

|

Pressing process |

Advanced pressing equipment makes the brass wire evenly arranged and firmly pressed on the brush base |

Ensures that the bristles are evenly distributed, providing stable and consistent processing effects during operation |

|

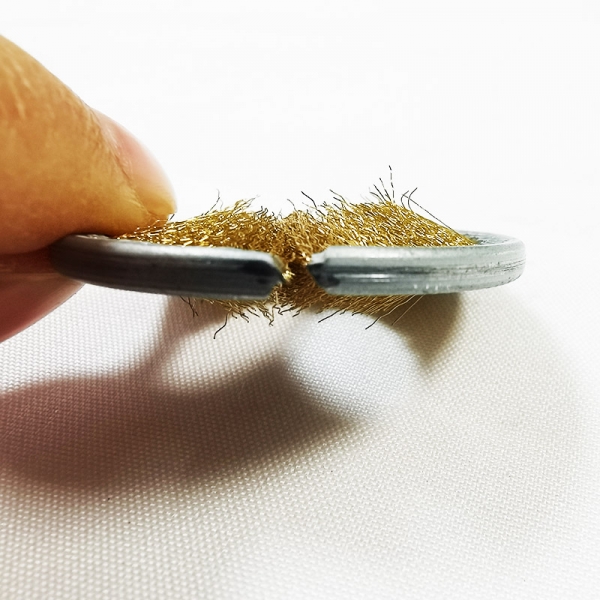

Winding process |

Twist the cotton thread tightly around the metal wire, firmly combined, and the bristles are durable |

Improve efficiency, strong structure, not easy to deform |

.jpg)

3. Product Features

-Efficient cleaning: The arc-shaped design increases the contact area and allows for quick and comprehensive cleaning.

-Strong durability: High-quality materials and processes, wear-resistant, corrosion-resistant, and suitable for high-intensity use.

-Widely applicable: Suitable for surface treatment of a variety of materials.

-Customized service: The brass wire thickness, brush density, size, etc. can be customized according to needs.

-Easy to operate: The structural design is easy to install and use, and is suitable for all types of industrial equipment.

4. Application areas

-Metal processing: Grinding, deburring, and rust removal of parts to improve accuracy and life.

-Machinery manufacturing: Equipment cleaning, maintenance, and surface treatment to ensure stable operation of equipment.

-Furniture production: Grinding and polishing of wood surfaces to enhance texture and lay the foundation for painting.

-Electronic equipment manufacturing: Grinding and cleaning of the outer shell and internal metal parts to ensure performance.

.jpg)

5. Quality assurance system

1. Strict control of raw materials: Strict inspection of brass wire and metal substrate to ensure quality.

2. Production process

Raw material inspection → Brass wire winding → Fixing treatment → Initial quality inspection → Performance test → Finished product packaging → Sampling inspection and storage

3. Transportation protection

-Independent PE sealed bag packaging, cardboard box pressure-resistant packaging.

-Mark product information for easy use

.jpg)

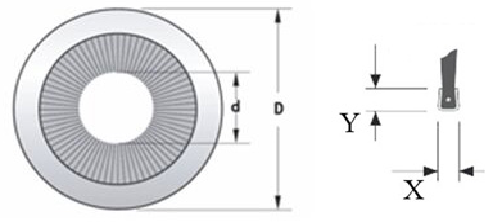

Customized Product

We can make customized the specification as requirement.The following are product drawings, if you request other size, please contact our sales team to provide the information shown in the drawing, we can make customized for your application.

|

Specification |

|

|

Bristles Material |

Brass wire |

|

Other Bristles Material |

Nylon,PP,Steel Wire,Stainless Steel Wire.etc |

|

base material |

Steel wire/Galvanized Iron |

|

Base size |

3#,4#,5#,6#,7#,8#,customized |

|

Outer diameter |

35mm |

|

Inner diameter |

10mm |

|

Wire diameter |

0.1mm |

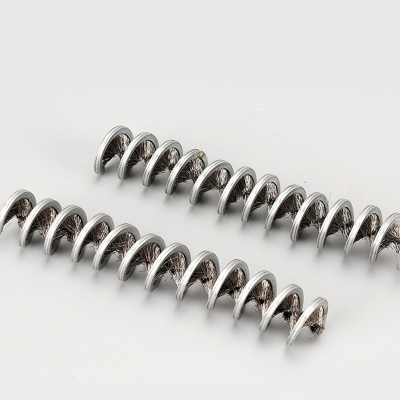

Similar and customized products

We are a professional manufacturer and supplier of industrial brushes, and we have a variety of materials and types of tube cleaning brushes for you to choose, contact us to customize your products!

.jpg)

Other Types of Coil Brushes