Product Description

1. Product Overview

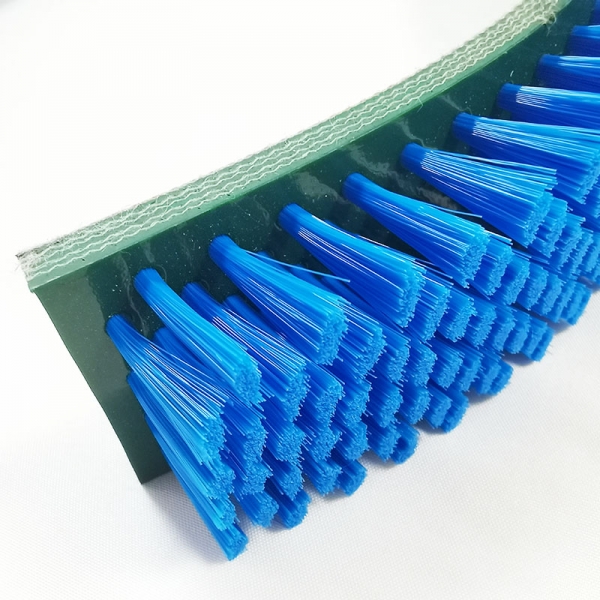

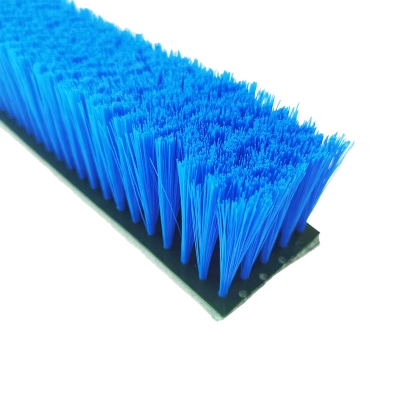

This nylon belt brush is made of high-quality wear-resistant nylon bristles and a flexible plastic base. It is made through a precise bristle planting process and is suitable for industrial scenes such as metal processing, wood processing, electronic manufacturing, and automobile production. It can efficiently clean impurities and fit complex surfaces, taking into account durability and customization needs.

.jpg)

2. Material and craftsmanship

- Bristles: Ultra-high-density nylon bristles (0.2mm diameter) penetrate the gaps in the belt to remove adhesives

- Substrate: Antistatic polymer base prevents secondary adsorption of dust

- Craftsmanship: Precision hair planting technology, evenly arranged bristles, no dead corners. Supports long strips, rings and multiple colors.

.jpg)

.jpg)

3. Advantages Analysis

-Performance and Cost

(1) Durability and Cost Reduction: High-quality materials extend service life, reduce replacement frequency, and reduce comprehensive use costs.

(2) Efficiency and Labor Saving: Efficient cleaning shortens operation time, improves efficiency, and reduces labor cost investment.

-Customization and Service

(1) Flexible Customization: Supports customization of size and bristle density to match the personalized cleaning needs of equipment.

(2) Quality Control: Strictly control the entire production process, and check every level from raw material detection to finished product delivery to ensure industrial-grade standards.

.jpg)

.jpg)

.jpg)

.jpg)

4. Application fields

- Metal processing: clean impurities on the surface of parts, maintain key parts of equipment, ensure processing accuracy and equipment stability.

- Wood processing: process the surface of boards, clean processing machinery, improve wood quality, and extend equipment life.

- Electronic manufacturing: remove impurities on electronic components and equipment to ensure stable performance and reduce failures.

- Automobile manufacturing: clean oil and carbon deposits on parts, process the surface of the car body, and improve the performance of parts and coating quality.

5. Industrial application scenarios

Metal processing: remove impurities from parts, maintain equipment accuracy, and ensure processing stability.

Wood processing: process board debris, clean mechanical parts, and improve the quality of wood products.

Electronic manufacturing: remove dust particles from components to ensure stable device performance and reduce failures.

Automobile manufacturing: clean oil and carbon deposits from parts, optimize body surface treatment, and improve painting quality.

6. Why choose us

(1) Cost-effectiveness

-Durable and cost-saving: high-quality materials and processes increase the service life of the brush and reduce replacement costs.

-High efficiency and efficiency improvement: strong cleaning power, greatly shorten cleaning time, improve work efficiency, and reduce labor costs.

-Competitive price: self-produced and self-sold, direct access to the source. While ensuring quality, control costs and have a high cost-effectiveness.

(2) Additional advantages

-Professional support: a professional team provides technical support at any time to solve product-related problems.

-Good reputation: win the trust and support of customers with excellent performance and reliable quality.We can make customized the

specification as requirement.

The following are product drawings, if you request other size, please contact our sales team to provide the information shown in the drawing, we can make customized for your application.

.jpg)

Different base materials are available

.jpg)

Similar and customized products

Other similar products or customized products made by HUIXI.We are a professional manufacturer and supplier of industrial brushes, and we have a variety of materials and types of Belt brushes for you to choose, contact us to customize your products!

.jpg)