Product Description

|

Total length |

Diameter |

Bristle working part length |

Rod length |

Rod diameter |

Bristles material |

Grit size |

|

150mm customized |

35mm customized |

40mm customized |

110mm customized |

8mm |

Silicon carbide customized |

#80 |

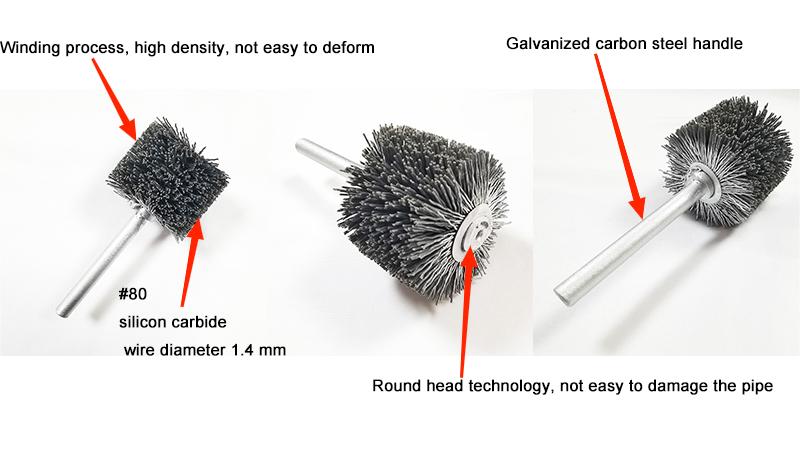

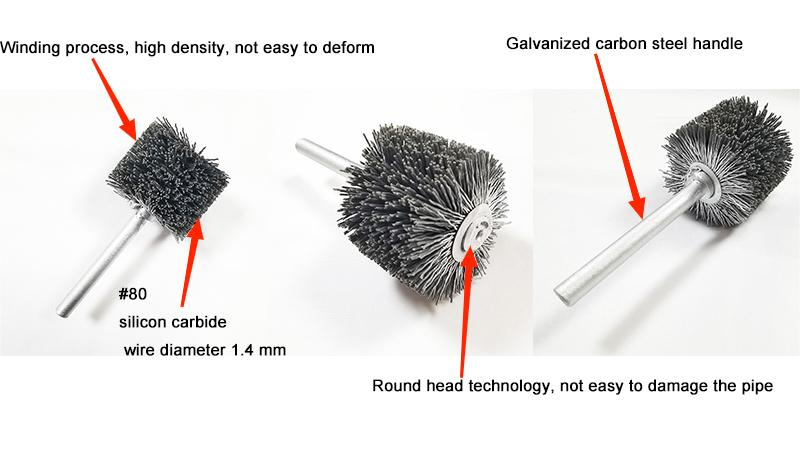

1. Production process

Using cutting-edge winding technology, the special abrasive wire is tightly and orderly wound on the brush body frame. With high-precision equipment, the abrasive wire spacing and winding angle are precisely controlled. The brush body frame has been specially treated to have excellent toughness and corrosion resistance, providing a stable support for the abrasive wire, ensuring that the abrasive wire does not fall off under complex working conditions, and achieving long-term and stable grinding.

.jpg)

2. Product highlights

- High-density bristles, grinding efficiency improvement: the abrasive wires are closely arranged, greatly expanding the contact area with the workpiece. Whether it is a large area of rough surface or a complex shape of cracks and corners, stains, rust, burrs and processing defects can be quickly removed, greatly shortening the grinding time and improving work efficiency.

- High-quality materials, wear-resistant and durable: Selected super-hard and wear-resistant abrasive wires, high hardness and strong wear resistance. In the face of high-intensity grinding, the abrasive wire is not easy to wear and deform, always maintaining a good grinding effect, extending the service life of the brush and reducing the cost of use.

- Flexible adaptation, multi-scenario grinding: The design is flexible and can be adapted to parts and pipes of different diameters and shapes. Whether it is the inner wall of a slender pipe or a special-shaped part with a complex structure, it can go deep into it to achieve all-round grinding without dead angles to meet various industrial needs.

- Customized service to meet individual needs: According to the customer‘s requirements for brush size, shape, bristle density, etc., tailor-made exclusive abrasive wire channel brushes are made to seamlessly connect the production process.

- Multiple materials to adapt to complex working conditions: Silicon carbide, aluminum oxide and other abrasive wire materials are provided. Silicon carbide is suitable for high-hardness metal grinding; aluminum oxide takes into account hardness and scratch resistance, and can be flexibly selected according to the grinding object and environment.

3. Application field

- Mechanical parts processing: In mechanical manufacturing, it is used to grind metal parts such as engine cylinders, gears, shafts, etc., remove processing marks, oxide scale and burrs, improve the surface finish of parts, and ensure dimensional accuracy and assembly quality.

- Pipeline inner wall treatment: For pipelines in industries such as petroleum, chemical industry, and water treatment, it solves the problems of scaling and corrosion on the inner wall. Go deep into the pipe, efficiently clean dirt and rust, restore the pipe flow capacity, and extend the service life.

- Electronic component manufacturing: For precision metal or ceramic electronic components, with precise grinding ability and fine bristles, high-quality grinding is completed without damaging the components to meet the surface flatness and finish requirements.

4. Grinding effect

The surface of the workpiece after grinding is smooth, perfectly presenting the metallic luster or the original texture of the material, significantly improving the appearance quality and added value of the product. During mass production, the grinding effect is stable to ensure that each workpiece meets high standards.

5. Product quality

- Strictly selected materials: Abrasive wires are made of high-purity, high-performance materials, taking into account hardness, wear resistance and flexibility. The brush body frame uses high-strength, corrosion-resistant alloys to provide a solid support foundation for abrasive wires.

- Fine production process: Introduce advanced equipment and automation lines, monitor semi-finished products in real time, and ensure quality.

- Strict quality inspection: Build a complete inspection system, and only qualified products are shipped to ensure stable application.

- Safe packaging design: Use special materials to package to prevent damage during transportation and storage, and mark product information for easy identification and use by customers.

- Logistics cooperation guarantee: Cooperate with reputable logistics service providers to ensure that products can be delivered to customers in a timely and safe manner.

We can make customized the specification as requirement.

The following are product drawings, if you request other size, please contact our sales team to provide the information shown in the drawing, we can make customized for your application.

Total length: 150mm,customized

Diameter: 35mm,customized

Bristle working part length: 40mm,customized

Rod length: 110mm,customized

Rod diameter: 8mm

Bristles material: Silicon carbide,customized

Grit size: #80

.jpg)

Similar and customized products

Other similar products or customized products made by HUIXI.We are a professional manufacturer and supplier of industrial brushes, and we have a variety of materials and types of tube brushes for you to choose, contact us to customize your products!

.jpg)