Product Description

1. Product Overview

(I) Product Definition and Overview

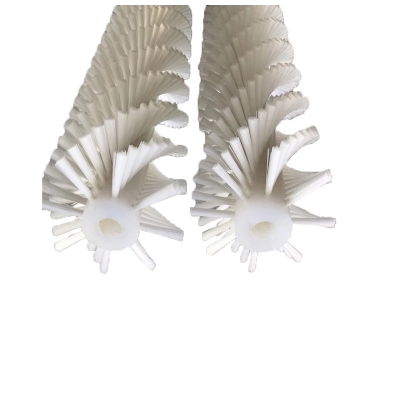

This nylon wire roller brush uses advanced winding technology to tightly wind high-quality nylon wire around the shaft. The bristles are soft and densely arranged, and are designed to provide gentle and efficient cleaning services for items that are sensitive to surface damage. It is suitable for many fields such as electronics, optics, and glass..jpg)

2.Technology Highlights

|

Process dimensions |

Technical details |

User benefits |

|

Long strip brush production |

Selected nylon filaments are made into uniform long strips through special processes. Through the pressing process, the bristles are tightly combined with the metal base, and the bristles are not easy to fall off |

Strong durability, no need for frequent replacement, and reduced use costs |

|

Wrapping process |

High-precision equipment tightly winds the long nylon strip brush on the shaft, strictly controls the winding spacing, and ensures that the bristles are evenly distributed |

Forming high-density bristles, increasing the cleaning contact area, and cleaning efficiently and thoroughly |

.jpg)

3. Product Features

(I) Gentle Care

The bristles are soft and suitable for cleaning fragile items such as glass, LCD panels, and precision electronic components to avoid scratches.

(II) High-density cleaning

The tightly wound bristles can remove more stains with one wipe, and the cleaning efficiency is high.

(III) Durable and durable

The high-quality nylon wire is combined with a solid metal base, and the bristles are not easy to fall off and can withstand frequent use.

(IV) Customized service

The thickness of the nylon wire, the density of the bristles, and the size of the roller brush can be customized to meet different cleaning needs.

(V) Adaptive equipment

Designed for use with automated cleaning machines and power tools, it is easy to install, has strong adaptability, and improves the cleaning efficiency of the equipment.

.jpg)

IV. Application areas

(I) Electronic display manufacturing

Used for cleaning glass substrates and LCD panels to remove dust and oil to ensure display effects.

(II) Optical instrument production

Clean optical lenses and lenses to avoid damaging the coating and ensure image quality.

(III) Precision electronic component cleaning

Safely remove impurities on the surface of integrated circuit boards and chips to prevent circuit failures.

(IV) Glass cleaning

Used for cleaning glassware and car windshields to maintain smoothness.

.jpg)

V. Quality assurance system

(I) Strict control of raw materials

Strict quality inspection is carried out on each batch of nylon raw materials purchased to ensure that its softness, strength, wear resistance and other indicators meet high standards. At the same time, the metal base is tested for corrosion resistance, strength and other performances to ensure product quality from the source.

(II) Production process

Raw material inspection → Nylon strip production (sheeting process) → Winding to shaft → Preliminary quality inspection → Performance sampling → Packaging

(III) Transportation protection

Use cardboard boxes or plywood boxes for packaging, and set up buffer materials inside to prevent the roller brush from collision and extrusion during transportation.

Customized Product

We can make customized the specification as requirement.The following are product drawings, if you request other size, please contact our sales team to provide the information shown in the drawing, we can make customized for your application.

|

Specification |

|

|

Bristles Material |

Nylon |

|

Shaft material |

Stainless Steel |

|

Total Length |

1000mm |

|

Bristle working part length |

800mm |

|

Outer diameter |

55mm |

|

Shaft diameter |

20mm |

|

Style |

With shaft |

|

Other sizes |

Customizable |

Similar and customized products

We are a professional manufacturer and supplier of industrial brushes, and we have a variety of materials and types of tube cleaning brushes for you to choose, contact us to customize your products!

.jpg)

Other Type Roller Brush

1-Tufted Craft Roller Brush

2-Winding process roller brush

3-Roller Brush without shaft