How Do You Know About Deburring Brushes?

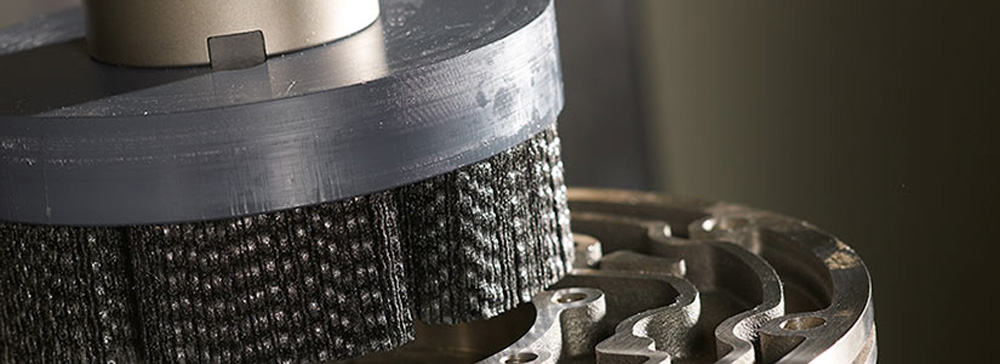

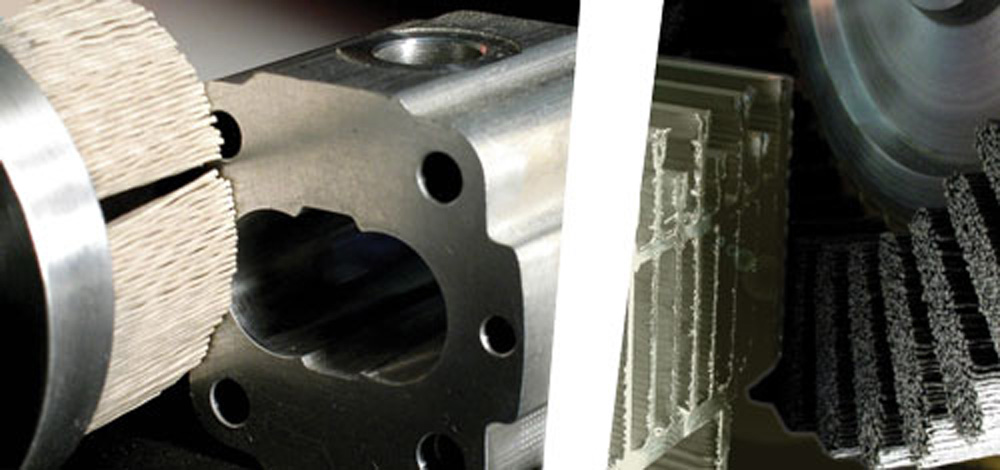

Deburring is an important step in some industries such as in aerospace and automotive, even the smallest remaining burr can negatively impact the operation. Finishing problems can be easily overcome by selecting the right tool specifications for the application, ensuring a burr-free, consistent finish without damaging the project.

Huixi company supplies customized deburring brushes in various shapes like disc, wheel, spiral, twisted, etc. The main abrasive materials include silicon carbide, aluminum oxide, and diamond. Grit from #60 to #1000. These brushes are made from massive PU with abrasive nylon grits. They are widely and perfectly used for structuring wood, removing rust from metal surfaces, cleaning or heavy dirty surfaces, porches, and terraces made from stone or wood.

Abrasive grains are embedded in the entire length of the bristles so the sides act like flexible files. These brushes remove workpiece material as well as surface contamination in a single step. The nylon bristles do not scratch and are appropriate for cleaning and wood polishing, stainless steel, and aluminum treatment. These disc brushes won‘t leave behind debris that could cause rust on your workpiece. Also, they are good for acids and alkalies application.

Wide application of deburring brushes:

1. On any flat machined auto parts

2. Deburring on milled casting and forgings

3. Edge blending and edge radius

4. Fine blank deburring process

5. Remove burrs on engine blocks and cylinder heads

6. Remove any rust and scale

7. Cleaning of pre-cast concrete molds

8. Woodworking like sanding and texturing