Find Correct Strip Brushes for Your Seal Trouble

Huixi supply a wide rage of custom brushes including industrial brushes, and machine guarding for all types of brush seal applications and industrial machinery. Our brush seals, brush laths, metal channel strip brushes, disk seals, ring seals, staple set brushes, cup brush seals and cylindrical coil brush seals reduce the movement of air, restrict smoke and fumes, screen out the noise and static and dampen vibrations.

Our brush strips are available in thousands of standard or custom configurations to control like noise, chips, light, dust, vibration, air, coolant mist, and temperature. Huixi flexible strip brush is a flexible metal-free brush designed to reduce the cost of hardware associated with metal constructions.

.gif)

.gif)

Plastic base flexible strip brushes, hot-melt new technology strip brushes are mostly used to install movable doors and windows, revolving doors, smooth doors, automatic doors, elevators. The seal strip brush is used to block dust and prevent dust from entering the interior. Buses, subways, trains, elevators, etc. are equipped with corresponding strip brush supporting products.

Widely used in various types of automatic doors, revolving doors, smooth doors, steel structure doors, and cleaning, cleaning, dustproof, sealing, etc. of machinery and equipment.

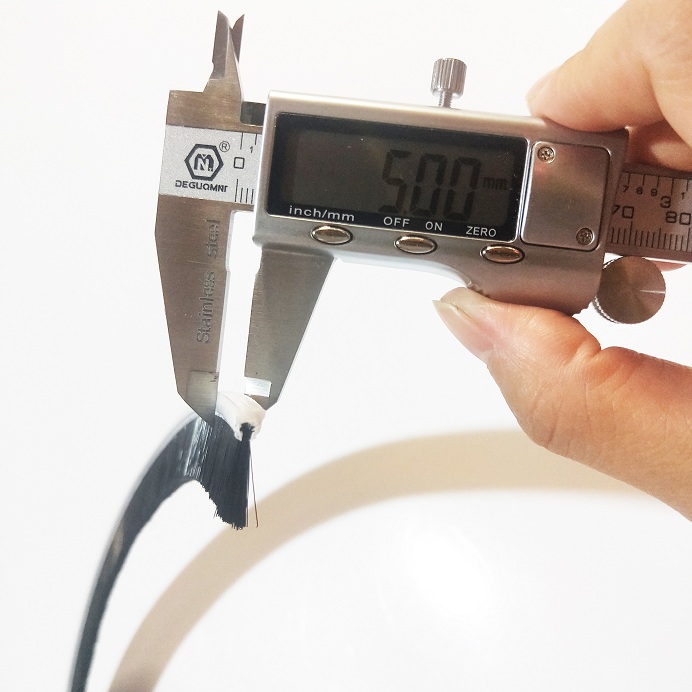

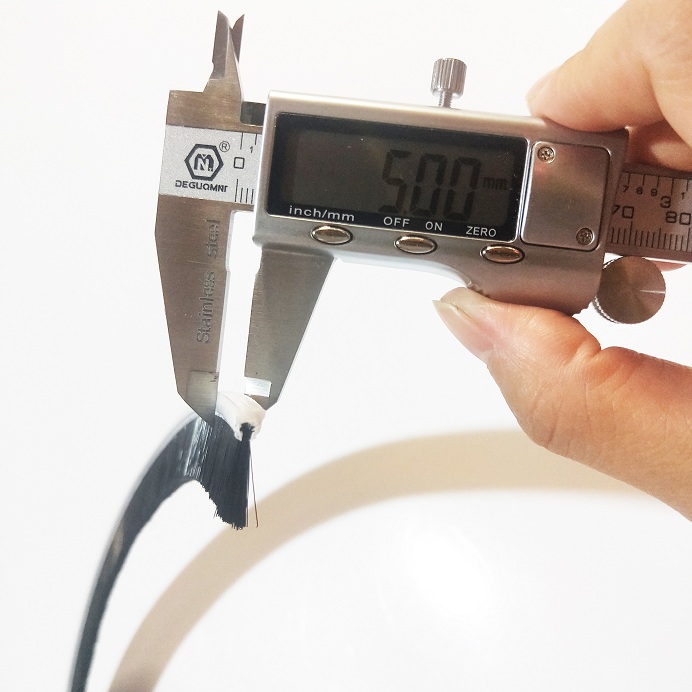

The specifications of the plastic bottoms are available in 3*3mm, 4*4mm, 5*5mm, 6*6mm, 7*7mm, 8*8mm. The wire diameter, material and height of the hair are not limited to the length of the brush. Brush strips can be supplied as require length or as a whole roll.

The plastic bottom strip brush can be wound and rotated on the steel pipe or steel rod to make an industrial brush roller. It is produced by German equipment, with new technology and high technical content. Compared with industrial brush rollers produced by traditional processes, flexible strip spiraled brush rollers have advantages of

1. The spiral rotating bristles are evenly distributed, and the industrial brushes produced by the traditional process have the disadvantages of uneven density and length of the brush wire.

2. The bristles and the base are hot-melt bags, so they do not depilate, and the brush rollers of the traditional process are steel nail clips planted into the holes or single steel belt clips, and the metal is easy to rust or dehair.

3. The plastic strip brush can be curled arbitrarily, the packaging and transportation are convenient, and the weight is light, thereby reducing the freight cost.