Product Description

|

Total Length |

Bristles length |

Base thickness |

Base height |

Channel base |

Material |

Color |

Packaging |

|

700mm~1400mm/customized |

90mm |

20mm |

30mm |

galvanized steel |

polypropylene + steel wire |

white/red |

Hard carton/plywood box |

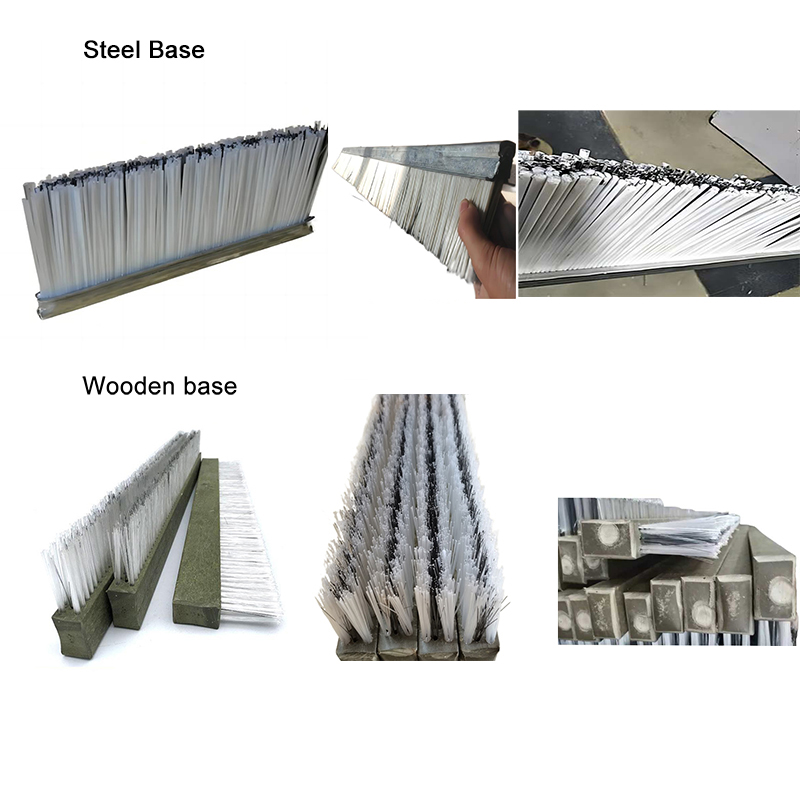

1. Exquisite craftsmanship:

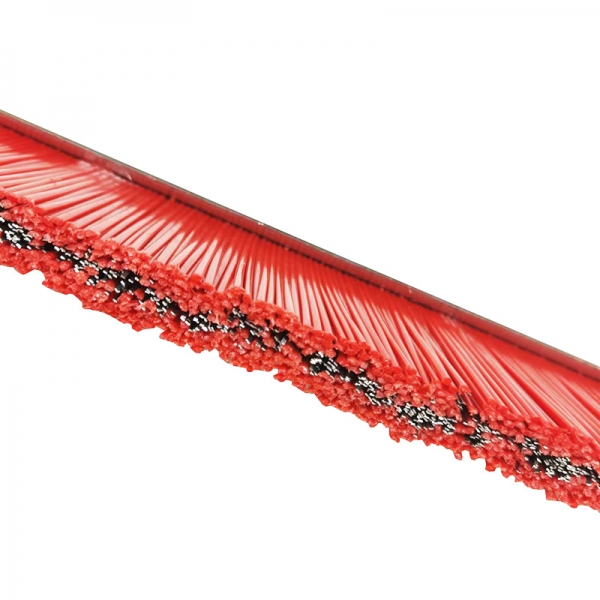

The steel base of our block machine cleaning strip brush adopts advanced manufacturing technology, combined with a mixed bristle design of plastic wire (red polypropylene) and flat steel wire, ensuring its excellent performance in wear resistance and cleaning efficiency. This unique structural design makes the strip brush more efficient in handling dust and debris on the brick machine production line, while ensuring long-term stability and durability.

2. Product highlights:

- Wear-resistant material: PP material combined with steel wire, this combination provides excellent wear resistance, effectively removes dust from the surface of bricks, and is suitable for high-intensity industrial cleaning and maintenance work.

- Sturdy steel base: The base is made of galvanized iron. This design enhances the firmness of the overall structure, ensures the stability and durability of the strip brush during use, and extends the service life of the product.

- Efficient cleaning: The optimized bristle arrangement ensures uniform cleaning effect and improves cleaning efficiency.

- Customized service: According to the needs of different production lines, customized services of various sizes and shapes are provided to ensure a perfect fit for your equipment.

3. Application areas:

- Brick making machinery cleaning: specially designed for block making machines, used to clean ash, stone powder, etc. on the equipment line to keep the equipment clean and efficient.

- Industrial maintenance: In the cleaning and maintenance of the surface of various industrial equipment, PP plus wire strip brush can effectively remove dust and dirt and improve equipment performance.

.jpg)

4. Effect:

This brush can provide consistent and reliable cleaning effects whether on the high-speed block making machine production line or in other industrial cleaning applications. The surface is clean without residue, which improves the overall quality and appearance of the product.

5. Product quality:

- Fine production: We strictly control every production process to ensure that every product meets the highest standards.

- Quality inspection: Each product undergoes strict quality inspection before leaving the factory to ensure reliable quality.

- Packaging protection: Use professional packaging materials to ensure the safety of products during transportation.

- Logistics cooperation: Cooperate with reputable logistics service providers to ensure that products can be delivered to customers in a timely and safe manner.

.jpg)

We can make customized the specification as requirement.

The following are product drawings, if you request other size, please contact our sales team to provide the information shown in the drawing, we can make customized for your application.

Total Length(L): 700mm~1400mm/customized other size

Bristles length(H):90mm

Base thickness(A):20mm

Base height(B):30mm

Material:polypropylene + steel wire

Standard Specifications Reference

|

Total Length(L) |

Overall height (H) |

Base (A*B) |

Base material |

Rows |

Filament |

|

1000mm |

100mm |

30*50 |

plastic |

3 |

steel |

|

1000mm |

100mm |

40*50 |

plastic |

3 |

steel+nylon |

|

920mm |

90mm |

20*25 |

metal |

- |

steel+nylon |

|

1000mm |

90mm |

20*25 |

metal |

- |

seel+polypropylene |

|

1400mm |

90mm |

20*25 |

metal |

- |

seel+polypropylene |

|

customized |

- |

- |

- |

- |

- |

Similar and customized products

Other similar products or customized products made by HUIXI