Product Description

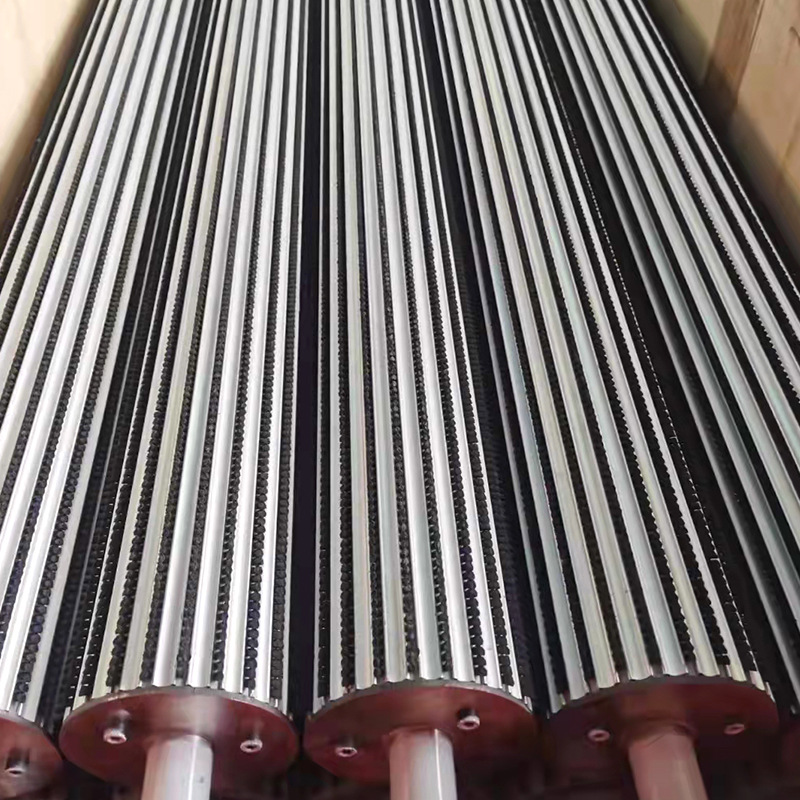

Product Overview

Designed for materials such as plastic film, textile fabric, paper, metal foil, etc., through the synergistic effect of nylon bristles and roller body, it can efficiently realize the expansion and flattening of materials, improve production quality and efficiency, and is the core auxiliary equipment for production lines in multiple industries.

.jpg)

Core Advantages

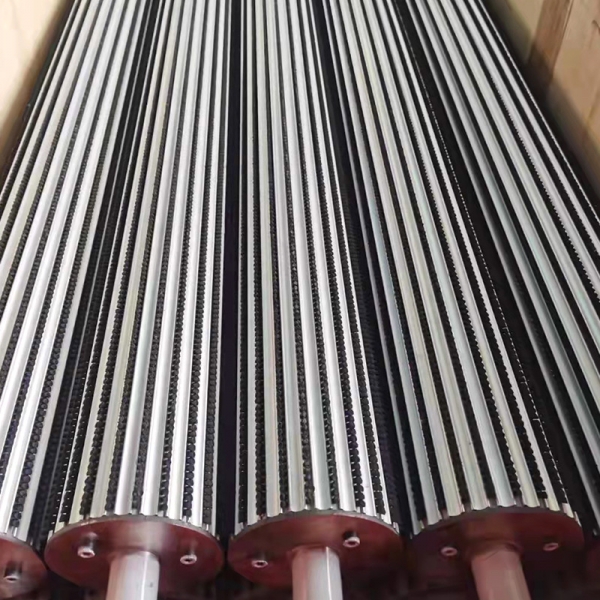

1. Soft and efficient, protecting materials

- Nylon bristles: selected high-toughness nylon material, wear-resistant and corrosion-resistant, can not only strongly unfold wrinkles, but also do not damage the surface of soft materials such as film and fabric, while the anti-static design reduces dust adsorption.

- Stable roller body: The metal roller body has strong rigidity, high-speed operation without deformation, and the bristles are evenly distributed to ensure that the material is uniformly stressed and the flattening effect is uniform and stable.

.jpg)

2. Applicable in multiple scenarios

- Plastic film: Process cast film, blown film, etc., eliminate wrinkles, and provide a flat base for printing and laminating processes.

- Textile printing and dyeing: open the width of knitted fabrics and non-woven fabrics to reduce printing and dyeing wrinkle defects and improve the yield rate.

- Papermaking/metal processing: flatten paper and metal foil to improve surface flatness and meet high-precision processing needs.

.jpg)

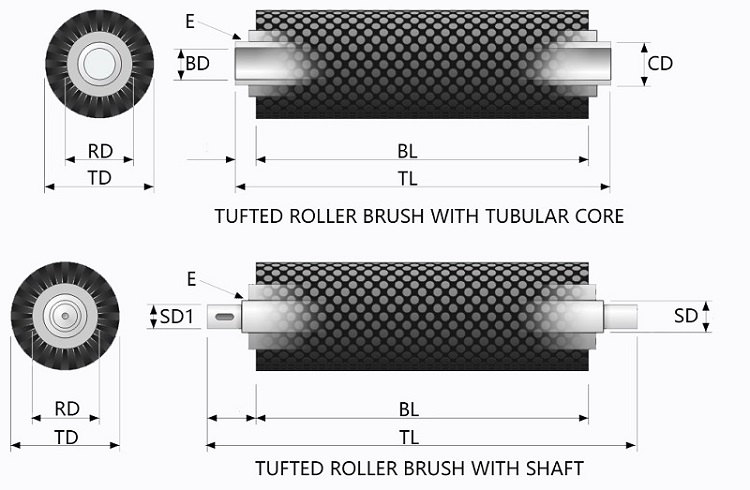

3. Customized service-create exclusive solutions on demand

Support all-round customization: customize the roller size (length/diameter), bristle density and hardness according to material thickness, width and equipment space.

4. Peace of mind in every step of cooperation

- Source control: 10 years of industrial brush production experience, full quality control from bristle selection to roller processing, each roller is strictly tested before leaving the factory, and the quality is stable and reliable.

- Fast delivery: support global logistics, provide real-time tracking information; customized products are delivered within fast proofing confirmation.

.jpg)

5. Similar product recommendations - more flattening solutions

(1)-Polyurethane flattening roller: strong elastic buffer, zero indentation, suitable for silk, ultra-thin film, and materials with extremely high surface precision requirements

(2)-Metal flattening roller: high rigidity and wear resistance, suitable for thick plates, metal foils, and high-strength flattening requirements for heavy industrial materials

(3)-Sponge flattening roller: soft and scratch-resistant, suitable for gentle flattening of optical films, electronic-grade materials, and precision electronic components

.jpg)